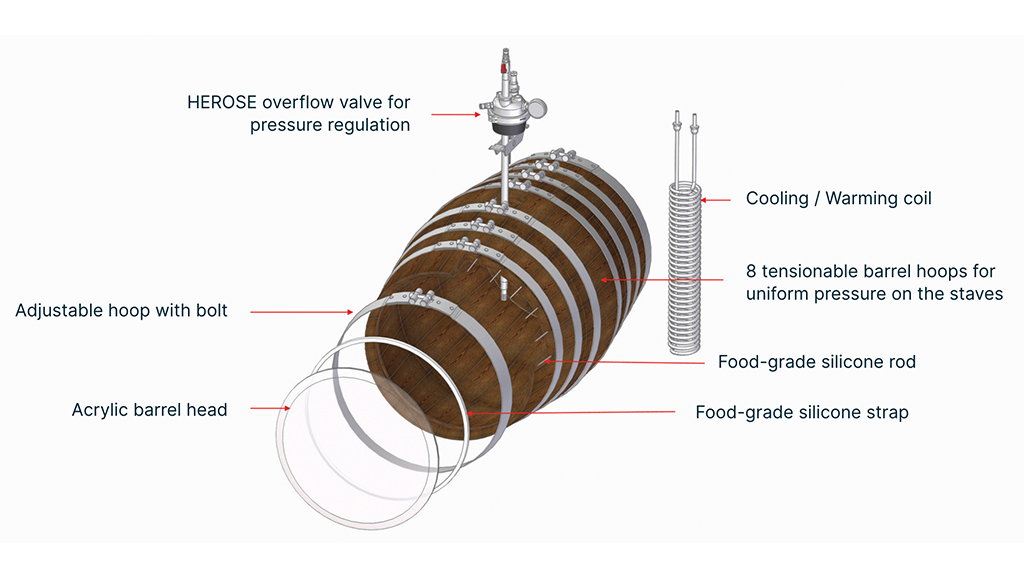

auric barrels is revolutionizing winemaking with the development of a novel barrel. A HEROSE pressure relief valve ensures pressure regulation within the barrel.

Various wines are produced at auric for testing purposes.

For wine lovers and many producers, a dream is becoming reality: wine made exclusively from grapes, yeast and bacteria. There’s no longer a need for sulphites or many other additives. The secret to this chemical-free wine production lies in the auric infinity technology pressure fermenter with stationary stainless steel bung, which enables the entire winemaking process to take place without air exposure. This gives producers complete control over their product’s oxidation, contamination and evaporation. The production process is so simplified that wine enthusiasts can now make quality wine.

Barrel maker Bruno Alexander Gantenbrink and engineer Vitalie Popa are opening a new winemaking chapter. The starting point was Popa’s desire to move away from sulphites and other additives in wine, which can act as allergens. His years of experience in Australian and New Zealand wine production led him to this idea. Planning and development began about seven years ago, and in 2021, Gantenbrink joined the project to produce the first trial series of the innovative barrels. Now, the partners are presenting their patented innovation – the auric infinity barrel – at SIMEI 2024 trade fair in Italy in mid-November.

What makes this barrel unique for winemaking?

In conventional wine barrels, the bung is typically made of silicone. During winemaking and aging the closure needs to be removed for various tasks, leading to oxidation, evaporation, and contamination of the product. Changes in air pressure and humidity in the wine cellar create positive or negative pressures inside the barrel, significantly affecting the sealing of the barrel’s silicone bung. The traditional barrel design with silicone bung does not adequately address these challenges. The innovative auric infinity pressure fermenter resolves all issues associated with conventional closures and enables wine production using only grapes, yeast, and bacteria. After years of research and development, this new barrel technology is entering the market. The system allows sampling without oxidation, contamination, or evaporation, marking a revolution in winemaking in wooden barrels.

If you can drink quality wine without additives, who will still choose conventional wine?

Vitalie Popa, Vinemaker und auric-infinity-developer

The cross-section clearly shows the special features of the new type of cask.

Fermentation in a wooden barrel at constant pressure

The auric infinity barrel allows for wine production using only grapes, yeast and bacteria under controlled, continuous pressure. This is where HEROSE plays a role in pressure regulation. While searching for a suitable partner for the groundbreaking barrel, Popa connected with HEROSE. The requirements called for a compact solution which optimally removes the resulting carbon dioxide and thus regulates the pressure. Additionally, the valve needed to be able to ventilate when necessary. Based on type 06205 pressure relief valve, the body, bonnet, and spindle were adapted and a pull ring was added. The disc and guide remained unchanged. In close collaboration with auric barrels, this customer-specific adjustment was successfully implemented. Gantenbrink particularly highlights HEROSE’s pragmatic approach and willingness to adapt to customer needs.

The quality of the barrels for winemaking begins in the forest

The wood used is crucial to the quality of the barrel. Premium wood from sessile oak and pedunculate oak is used, which has excellent durability under oxygen-free conditions, making it ideal for the production of wine and whiskey barrels. Alexander Gantenbrink has access to his own forest in Croatia, where he practices sustainable forestry. The journey from tree to barrel is long. The trees grow for around 120 to 140 years, after which the wood is cleaved, cut, and left to air-dry outdoors for at least 24 months for the standard 225-litre barrique barrels. In the first three months, the wood is also soaked to prevent it from drying too quickly and to wash away the green, undesirable tannins from the wood. This process removes bitterness through exposure to the elements. Due to the forest mapping system, complete traceability of the raw materials is possible. Each barrel’s wood can be traced back to the exact tree location via a barcode.

Between craftsmanship and 3D CNC milling robots

The rounded geometry of a classic barrel poses a manufacturing challenge. The outer diameter contains more material than the inner, and each stave has a curved shape.

A CNC machine mills a 3D geometry into the staves. auric barrels‘ factory, located in Našice, Croatia, has been in operation since 2016 and is one of the most modern in Europe. Thousands of staves of Slavonian oak are stored on-site for barrel production. In addition to the new auric infinity barrel, standard barrels in sizes from 50 to 6,000 litres and fermenters up to 40,000 litres are sold worldwide.

Tested and approved

Naturally, Vitalie Popa and Bruno Alexander Gantenbrink have produced their own wines using the new technology. A much-praised Chardonnay, for example, was ready for consumption after just 8 weeks – without any added sulphites or additives, which are known to cause headaches and the typical „hangover.“ To independently test the performance of the auric infinity technology, four barrels were provided to Geisenheim University in Germany, which specializes in viticulture and wine business. Their detailed report fully confirmed the technology‘s capabilities. The trials also revealed that yeast cells exposed to sunlight develop significantly stronger cell walls.

We believe our development will fundamentally change barrel-winemaking.

Bruno Alexander Gantenbrink, CEO of auric barrels

A revolutionary and versatile technology in winemaking

With auric infinity barrels, almost any wine enthusiast can produce their own wine from grape juice, yeast and bacteria. The process is simplified as sulphites and other additives are no longer needed. An online course will be available to provide interested parties with the necessary knowledge. To kick-start the business, auric is offering the first 2,000 infinity 225-litre barrels for €2,000 each. There is also an affordable method for anaerobic bottling using special patented screw caps that are part of the filling technology. While wine production is the first application for this new technology, the method of fermenting in wood under constant pressure is also of interest for beer, cider, vinegar, and other products. It remains to be seen how the market will respond to the new technology. The positive feedback from those who have tasted the additive-free wine raises high expectations.

auric barrels

Im kroatischen Našice steht eine der modernsten Fassfabriken Europas mit neuestem Maschinenpark, erfahrenen Handwerkern und umfangreichem Holzlager slawonischer Qualitätseichen. Das auric-infinity-Fass ermöglicht die Fermentation unter Druck und Luftabschluss.

auric-barrels.com | auric-infinity.com

Photos: auric barrels

Read the current digital customer magazine now!

Read the current digital customer magazine now!