In the Paris Climate Agreement, the global community decided that the economy should become greenhouse gas neutral between 2050 and 2100. In order to achieve the ambitious goals, a fundamental transformation of the energy system is necessary beyond the pure expansion of renewable energies. Hydrogen will play a crucial role, among other things in road transport. For HEROSE, one of the world’s leading manufacturers of cryogenic valves, this is an important business area of the future.

Zero emissions, fast fuelling times, long ranges and more and more experts are convinced that vehicles powered by hydrogen are the future of mobility. An important requirement: a nationwide network of petrol stations. Several car manufacturers and petrol station groups have founded H2Mobility for this purpose. For Germany, those responsible are planning to create around 300 of these filling stations by 2023. And H2Mobility is just one example.

Safe refueling, as fast as gasoline

The technical requirements for hydrogen filling stations are more stringent than for conventional ones: at the stations, the gas is stored in low-pressure storage tanks at around 20 bar. In the car tanks, however, the hydrogen has to be compressed much more because of the required energy density. So compressors first bring the gas up to 1,000 bar, then store it temporarily in high-pressure tanks. To prevent the gas from heating up too much during refuelling it passes through a pre-cooler. The refuelling process itself takes no longer than with petrol. It is controlled electronically and is regulated at 700-bar pressure in the tank. The range of a tank filling corresponds to that of an internal combustion engine. If the pressure rises unexpectedly, the safety valve opens and releases the excess pressure into the atmosphere unhindered. Since hydrogen is 13 times lighter than air, it immediately escapes upwards and is completely harmless. Valves to the highest safety standards are required between the petrol station store and the car tank – HEROSE can already deliver here (more on this at the end of the article).

Photo: Linde

Car manufacturers are increasingly relying on hydrogen

Like in electric cars, hydrogen cars are powered by an electric motor. However, the electricity does not come from a battery but from a fuel cell. Within this cell, a chemical reaction between hydrogen and oxygen creates this current. The big advantage: there are no emissions, only water vapour. Although the automotive industry is currently focussing on battery-electric drives, manufacturers are also increasingly using hydrogen technology.

Renewable electricity becomes hydrogen

Fossil raw materials are still the most important source for the production of hydrogen. The most economical method is steam reforming: steam and natural gas are converted to hydrogen and carbon dioxide at temperatures of around 800 °C using a catalyst. Disadvantages: this type of production releases CO2, among other things, and is energy intensive.

“That is why the electrolytic production of hydrogen from renewable electricity – power to gas – is becoming a key technology,” says Prof. Dr. Hans-Martin Henning, spokesman for the Fraunhofer Energy Alliance and head of the Fraunhofer Institute for Solar Energy Systems ISE. “He can make mobility more climate-friendly by using cars, buses and trains to run almost emission-free over long distances using fuel cells. Hydrogen also offers the option of storing renewable energies – for example within the existing natural gas network. It can be converted back into electricity in so-called CHP plants, so that processes in refineries or steel making, for example, can be operated without emissions. The potential is manifold.”

Numerous projects are running to generate “clean” hydrogen, for example:

A joint hydrogen strategy of the five coastal states of Hamburg, Schleswig-Holstein, Lower Saxony, Mecklenburg-Vorpommern and Bremen is being coordinated by Hamburg’s Senator for Economics Michael Westhagemann. He says: “Northern Germany will play a much more important role in energy supply in the future than it does today, due in particular to the large amount of electricity generated from wind farms on the coasts and at sea,”. And further: “You have to be able to save it and hydrogen is very well suited for that. “And Gunnar Groebler, who is responsible for renewable energy at Vattenfall, says,” We expect to be able to use electricity from offshore plants near the coast, such as Brunsbüttel, for the electrolysis of hydrogen in the future”.

In Reußenköge near Husum, the company GP Joule is building Germany’s largest complete supply chain for “green” hydrogen. As part of the “e-Farm” project, which is funded by the Federal Ministry of Transport with eight million euros, GP Joule is building five electrolysis plants right next to wind farms. The hydrogen produced there will be sold at two filling stations in Husum and Niebüll. The project also includes two buses and five cars for public use. The waste heat produced by the electrolysis of hydrogen is to be fed into municipal heating grids.

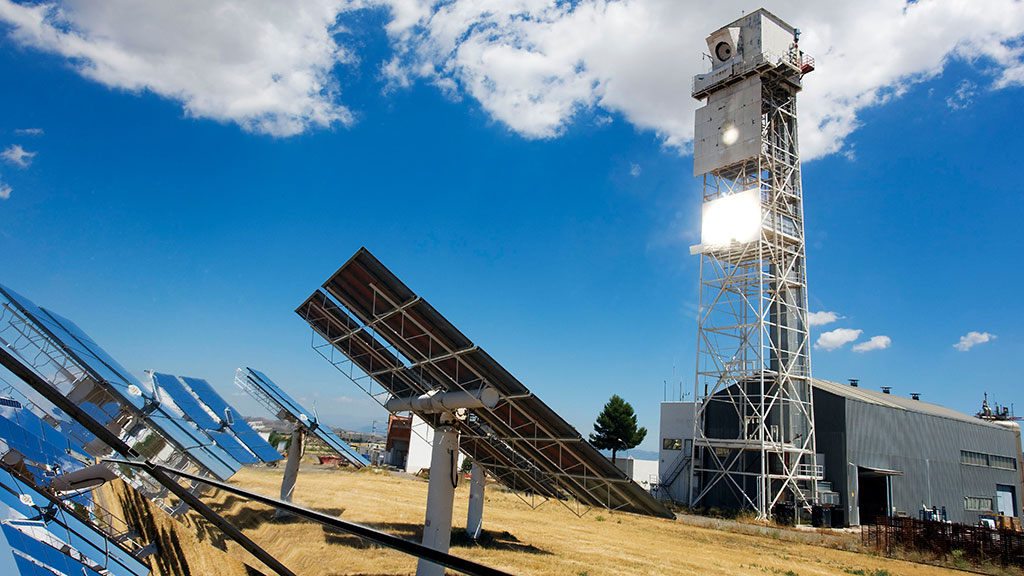

In Spain, the German Aerospace Centre (DLR) presented the largest system for solar thermal water splitting in November 2018. It is located near the Andalusian city of Almeria and is known as the “Hydrosol-Plant”. Mirrors with a total area of 3,500 square meters direct the sunlight onto a reactor and heat it up to 1,400 °C. Ceramic foams in the reactor lose oxygen. In a second step, water vapour is allowed to enter the machine, which in turn releases oxygen to the foams. What is left is hydrogen.

Hydrogen: top topic at HEROSE

As a leading valve manufacturer, HEROSE is closely involved with the subject of hydrogen and its many possibilities. Dirk Kohoutek, Product Manager of CRYOGENIC: “The challenges with hydrogen filling stations are, on the one hand, the high pressures of up to 1,000 bar and, on the other hand, the storage temperatures of -255 °Celsius. For comparison: LNG is -162 °Celsius cold, nitrogen -196 °Celsius. Kohoutek: “To ensure absolute tightness even under these conditions, we use bellows and offer valves that are milled from solid material – from V4A, for example.”

Did you like this article?

Please get further information and background reports about industrial valves and applications via the free HEROSE newsletter.

Subscribe here

Read the current digital customer magazine now!

Read the current digital customer magazine now!